- Identité d'entreprise

- Actes publiés

Identité de l'entreprise

Mentions SETI-TEC pour contrat

SETI-TEC, société par actions simplifiée, au capital social de 55500,00 EURO, dont le siège social est situé au 25 RUE DE LAMIRAULT, 77090 COLLEGIEN, immatriculée au Registre du Commerce et des Sociétés de Meaux sous le numéro 480739127 représentée par M Ivo MALTIR agissant et ayant les pouvoirs nécessaires en tant que président.

Présentation de la société SETI-TEC

SETI-TEC, société par actions simplifiée, immatriculée sous le SIREN 480739127, est active depuis 19 ans. Localisée à COLLEGIEN (77090), elle est spécialisée dans le secteur d'activité de la mécanique industrielle. Son effectif est compris entre 20 et 49 salariés. Sur l'année 2022 elle réalise un chiffre d'affaires de 24743900,00 EU. Le total du bilan a augmenté de 20,14 % entre 2021 et 2022. Societe.com recense 4 établissements ainsi que 11 mandataires depuis le début de son activité, le dernier événement notable de cette entreprise date du 20-10-2020. Ivo MALTIR est président de la société SETI-TEC.

Renseignements juridiques

| Date création entreprise | 03-01-2005 - il y a 19 ans Statuts constitutifschevron_right | ||||

Voir l'historiqueexpand_more Forme juridique SASU Société par actions simplifiée à associé unique Historique Du 21-09-2022 à aujourd'hui 1 an, 6 mois et 30 jours SASU Société par actions simplifiée à associé unique Du XX-XX-XXXX au XX-XX-XXXX X XXX XX XXXX XX X XXXX S....... Du XX-XX-XXXX au XX-XX-XXXX X XXXX X XXXX XX X XXXXX S....... Du XX-XX-XXXX au XX-XX-XXXX X XXXX X XXXX XX XX XXXXX S....... Du 10-06-2019 à aujourd'hui 4 ans, 10 mois et 10 jours Société par actions simplifiée Du XX-XX-XXXX au XX-XX-XXXX X XXXX X XXXX XX XX XXXXX S....... Du XX-XX-XXXX au XX-XX-XXXX X XXXX XX XXXX XX XX XXXXX S....... | |||||

| Noms commerciaux | SETI-TEC | ||||

| |||||

| Adresse postale | 25 RUE DE LAMIRAULT 77090 COLLEGIEN | ||||

| Numéros d'identification | |||||

| Numéro SIREN | 480739127 | ||||

| Numéro SIRET (siège) | 48073912700045 | ||||

| Numéro TVA Intracommunautaire | FR53480739127 | ||||

| Numéro RCS | Meaux B 480 739 127 | ||||

| Informations commerciales | |||||

Voir l'historiqueexpand_more Activité (Code NAF ou APE) Mécanique industrielle (2562B) Historique Du 27-01-2009 à aujourd'hui 15 ans, 2 mois et 23 jours Mécanique industrielle (2562B) Du XX-XX-XXXX au XX-XX-XXXX X XXXX XX XXXX XX X XXXXX M....... (2.......) Du 01-01-2008 à aujourd'hui 16 ans, 3 mois et 18 jours Mécanique industrielle (2562B) Du XX-XX-XXXX au XX-XX-XXXX X XXXX XX XXXX XX XX XXXXX M....... (2.......) | |||||

| Activité principale déclarée | concéption, fabrication et commercialisation d'ensembles mécaniques. | ||||

| Convention collective déduite: | Métallurgie cadres (650) | ||||

| Informations juridiques | |||||

| Statut RCS | doneINSCRITE - au greffe de Meaux Extrait d'immatriculation RCSfile_download | ||||

| Statut INSEE | doneINSCRITE Extrait d'immatriculation SIRENEfile_download | ||||

| Date d'immatriculation RCS | Immatriculée au RCS le 02-02-2005 | ||||

| Date d'enregistrement INSEE | Enregistrée à l'INSEE le 03-01-2005 | ||||

| Taille de l'entreprise | |||||

Voir l'historiqueexpand_more Effectif (tranche INSEE à 18 mois) 20 à 49 salariés Historique Du 03-01-2005 à aujourd'hui 19 ans, 3 mois et 17 jours 20 à 49 salariés | |||||

Voir l'historiqueexpand_more Capital social 55500,00 EURO Historique Du 30-01-2007 à aujourd'hui 17 ans, 2 mois et 20 jours Capital social : 55500,00 EURO Du XX-XX-XXXX au XX-XX-XXXX X XXX XX XXXX XX X XXXXX C....... : XXXXXXXX XXXX | |||||

| Chiffre d'affaires 2022 | 24743900.00 EU | ||||

Score extra-financier de la société SETI-TEC

Le score extra-financier évalue sur une année la performance d'une entreprise en matière sociale, fiscale et territoriale.

C

Score de 2021

- A

- B

- C

- D

- E

Le score territorial valorise les entreprises implantées dans des territoires économiquement défavorisés.

Le score social représente la capacité de l'entreprise à créer de l'emploi sur le territoire national à partir de sa valeur générée.

Le score fiscal représente la capacité de l'entreprise à reverser de la fiscalité aux territoires à partir de sa valeur générée.

Les 6 dirigeants de la société SETI-TEC

Dirigeants mandataires de SETI-TEC :

Mandataires de type : Président

| Depuis le 10-05-2018 | M Ivo MALTIR |

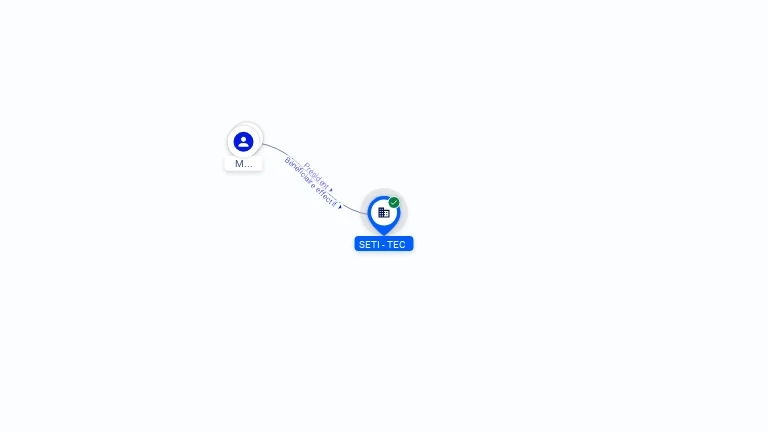

hubLa cartographie fait peau neuve !

Nos nouvelles fonctionnalités vous offrent une expérience améliorée pour explorer notre réseau de 10 millions d'entreprises et plus de 9 millions de dirigeants.

DécouvrirCartographie de la société SETI-TEC

Accédez aux réseaux complets de l'entreprise SETI-TEC, parmi les 10 millions d'entreprises et les plus de 9 millions de dirigeants présents sur Société.com.

Explorer la cartographie

Explorer la cartographieLes bénéficiaires effectifs de la société SETI-TEC

Accéder à plus d'informations

Cette version est limitée. Pour voir l'intégralité des actionnaires, mandataires ou toutes autres personnes physiques qui contrôlent SETI-TEC, faites évoluer votre offre

Entreprises liées à SETI-TEC

Cité 2 fois entre 2005 et 2007

Dirigeants : Jean LEMIERRE , Jean-Laurent BONNAFE , Yann GERARDIN , Thierry LABORDE , Jacques ASCHENBROICH et 85 autres

Cité 1 fois en 2013

Dirigeants : David DUPONT-NOEL , Bertrand BOISSELIER , Bertrand BOISSELIER , Eric DELGOVE , Veronique CUISSOT et 19 autres

Documents officiels de l'entreprise

| Statuts numérisés | Voir un exemple | |||

|---|---|---|---|---|

| Décision(s) de l'associé unique - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Statuts constitutifs - Formation de société commerciale - Procès-verbal d'assemblée constitutive - Nomination de président - Procès-verbal d'assemblée constitutive - Nomination(s) de commissaire(s) aux comptes - Attestation bancaire | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Les derniers actes modificatifs numérisés | Voir un exemple | |||

|---|---|---|---|---|

| Extrait de procès-verbal - Transfert du siège social - Extrait de procès-verbal - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Extrait de procès-verbal - Modification(s) relative(s) au(x) commissaire(s) aux comptes | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Changement de président - Document relatif au bénéficiaire effectif | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Procès-verbal d'assemblée générale ordinaire - Démission(s) de commissaire(s) aux comptes | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Extrait de procès-verbal - Démission de directeur général | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Extrait de procès-verbal - Changement de président | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Procès-verbal d'assemblée générale ordinaire | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Changement de commissaire aux comptes suppléant | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Nomination de président | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Nomination de président | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Changement relatif à la date de clôture de l'exercice social - Décision(s) de l'associé unique - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) de l'associé unique - Changement relatif à la date de clôture de l'exercice social - Décision(s) de l'associé unique - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Extrait de procès-verbal - Changement relatif à la date de clôture de l'exercice social - Extrait de procès-verbal - Changement de président - Extrait de procès-verbal - Nomination de directeur général - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Extrait de procès-verbal - Changement relatif à la date de clôture de l'exercice social - Extrait de procès-verbal - Changement de président - Extrait de procès-verbal - Nomination de directeur général - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Décision(s) des associés - Changement relatif à la date de clôture de l'exercice social | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Procès-verbal d'assemblée générale - Transfert du siège social - Procès-verbal d'assemblée générale - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Procès-verbal d'assemblée générale - Transfert du siège social - Procès-verbal d'assemblée générale - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Procès-verbal d'assemblée générale - Transfert du siège social - Procès-verbal d'assemblée générale - Modification(s) statutaire(s) - Statuts mis à jour | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Procès-verbal de décision du dirigeant social - Augmentation du capital social - Procès-verbal d'assemblée générale - Augmentation du capital social - Procès-verbal d'assemblée générale - Modification(s) statutaire(s) - Rapport du commissaire aux comptes - Augmentation du capital social - Attestation - Attestation bancaire - Statuts mis à jour - Procès-verbal d'assemblée générale - Libération du capital social | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Procès-verbal de décision du dirigeant social - Augmentation du capital social - Procès-verbal d'assemblée générale - Augmentation du capital social - Procès-verbal d'assemblée générale - Modification(s) statutaire(s) - Rapport du commissaire aux comptes - Augmentation du capital social - Attestation - Attestation bancaire - Statuts mis à jour - Procès-verbal d'assemblée générale - Libération du capital social | 7,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Les derniers comptes annuels numérisés | Voir un exemple | |||

|---|---|---|---|---|

| Comptes annuels complets : Complets (Bilan, annexes, rapport de gestion, rapport du CAC, état des créances, ...) | 13,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Comptes annuels complets : Complets (Bilan, annexes, rapport de gestion, rapport du CAC, état des créances, ...) | 13,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Comptes annuels complets : Complets (Bilan, annexes, rapport de gestion, rapport du CAC, état des créances, ...) | 13,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Comptes annuels complets : Complets (Bilan, annexes, rapport de gestion, rapport du CAC, état des créances, ...) | 13,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Comptes annuels complets : Complets (Bilan, annexes, rapport de gestion, rapport du CAC, état des créances, ...) | 13,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Comptes annuels complets : Consolidés (Bilan, annexes, rapport de gestion, rapport du CAC, état des créances, ...) | 13,90€ | shopping_cartadd_circlecheck_circleAjouté | |

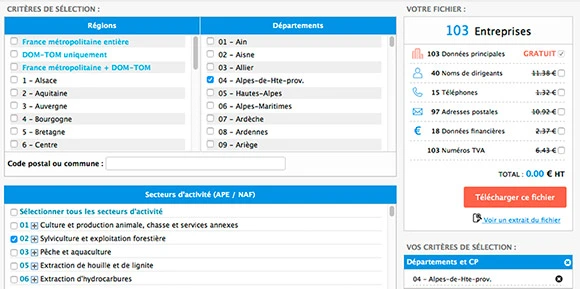

Trouver des prospects, des clients B2B

Prospectez les entreprises du même secteur d'activité et dans le même secteur géographique que la société SETI-TEC :

Prospectez les entreprises de Mécanique industrielle de Seine-et-Marne (77)

Chiffres clés de SETI-TEC

| Date de publication de l'exercice | 2023 | 31-12-2022 | Variation |

|---|---|---|---|

| Total du Bilan (Actif / Passif) | 15735200 EU | - - - | |

| dont Trésorerie | Voir le détail du bilan | ||

| dont Capitaux propres | Comptes non disponibles | 9541300 EU | - - - |

| dont Dettes | Voir le détail du bilan | ||

| Chiffre d'affaires | Publier votre dernier bilanfile_upload | 24743900 EU | - - - |

| Résultat net (Bénéfice ou Perte) | 6450200 EU | - - - | |

| Effectifs moyens | Non precise | - - - |

Les 30 Annonces d'évènements parues

| Date | Annonces légales (BODACC) | Prix | Achat | |

|---|---|---|---|---|

| Annonce BODACC - Comptes annuels et rapports (31/12/2022) | 2,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Annonce BODACC - Comptes annuels et rapports (31/12/2021) | 2,90€ | shopping_cartadd_circlecheck_circleAjouté | |

| Voir toutes les annonces légalesexpand_more | ||||

| Annonce BODACC - Comptes annuels et rapports (31/12/2006) | 2,90€ | shopping_cartadd_circlecheck_circleAjouté | |

Synthèse societe.com pour l'entreprise SETI-TEC

Equilibre Bilan

Favorable

Moyen

Défavorable

Rentabilité

Favorable

Moyen

Défavorable

4 établissements de la société SETI-TEC

SETI-TEC - 77090Actif

Etablissement Siège en activité depuis 4 ansAdresse : 25 RUE DE LAMIRAULT - 77090 COLLEGIEN

SETI-TEC - 77144Fermé

Ancien établissement en activité pendant 3 ansAdresse : 4 ALL DES TENNIS - 77144 MONTEVRAIN